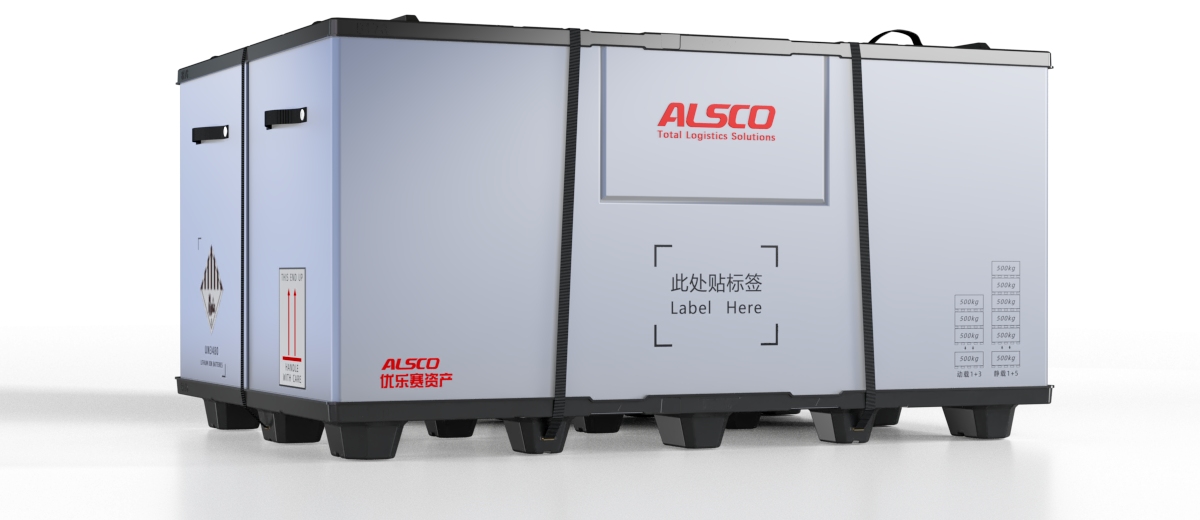

BIGBox

Oversized molding

Frame-type built-in steel pipe

Forklift interface size design

Tightening belt

As users demand for the high endurance of electric vehicles and the industry reduces the structure of new energy vehicles (battery, electronic control, motor) and the overall cost of the system, the modular transportation and packaging method has emerged, and the ALSCO BIGBox series , designed and developed for new energy vehicle battery packs and ultra-long automotive parts, breaking the rules, super large, and super load-bearing capacity.Advantages of the box: Marking around the large picture of the box

Adaptability

The size chain fully adapts to the container size design.

The BIGBox series products specifically include three models: B17, B15, and B13. On the premise that the width remains unchanged at 2270, the lengths are respectively designed to be 1690 (suitable for 7 40-foot containers) and 1320 (suitable for 8 40-foot containers). There are three specifications: 1185 (suitable for 9 40-foot containers). They are based on the ultimate design of the container, which can maximize the use of container space and help reduce internal consumption in the industry.

Advanced technology

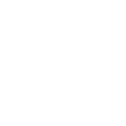

Ultra-large molding, the first in the industry

The base has introduced the world's leading GEISS T10 double-layer blister machine, which can produce oversized hoardings with high efficiency and high quality. The integrated molding ensures high-strength performance and can meet the load carrying, transportation and stacking of heavy objects.

Advanced structure

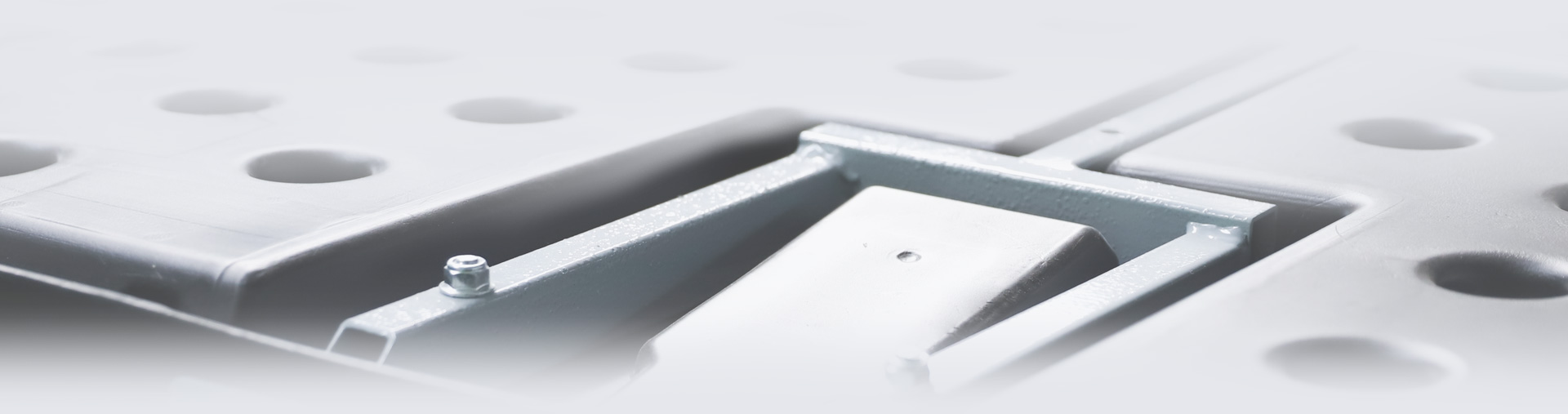

Stronger carrying capacity

Since batteries, motors and other components are heavy, how to avoid deformation of the bottom cover and ensure the sealing of the joints of the enclosure box? The bottom cover of the BIGBox series has built-in steel pipes and a frame-type steel pipe configuration, which is evenly stressed and has stronger load-bearing capacity. ; The hoardings adopt C-shaped, L-shaped, aluminum alloy and other hoarding configurations to ensure stable bearing capacity without neglecting the aesthetic appearance.

Supports mechanized operation of stacks

Easily handles large weight and volume

The BIGBox series optimizes the size design of the forklift interface and supports manual or mechanized operations (folding, stacking or unfolding) to ensure logistics handling efficiency.

The reliability of our products

Comes from our continuous efforts and verification

Comes from our continuous efforts and verification

All products of ALSCO have been verified by third-party testing agencies authorized by Ist

BIGBox

Oversized molding

Frame-type built-in steel pipe

Forklift interface size design

Tightening belt

BIGBox

| Model | Outer Size | Inner Size | Folded Height | Weight | Dynamic Loading(kg) | |

|---|---|---|---|---|---|---|

| N0. | L*W(mm) | L2*W2*H2(mm) | (mm) | (kg) | 3500g | 4200g |

| CS8 | 1200*800 | 1140*740*(H-200) | 1162*762*(H-120) | 27.5 | 250 | 350 |

| CS8 | 1200*800 | 1140*740*(H-200) | 1162*762*(H-120) | 27.5 | 250 | 350 |

| CS8 | 1200*800 | 1140*740*(H-200) | 1162*762*(H-120) | 27.5 | 250 | 350 |

The standard height:760/780/900/940/1000/1120/1150/1180mm

堆叠颠簸测试

堆叠颠簸测试 堆叠爬坡测试

堆叠爬坡测试 冷冻测试

冷冻测试 抗压测试

抗压测试 跌落测试

跌落测试 冲击测试

冲击测试