The solution value runs through the entire operation process and is committed to reducing costs, increasing efficiency, reducing carbon and saving energy.

-

Reduce packaging investmentReduce non-production investment, customers only need to rent according to actual needs.

-

Flexible production managementStandardized packaging brings convenience to logistics operations, and sufficient supply helps flexibly cope with production fluctuations.

-

Help reduce carbon emissionsThe average number of turnovers per box is more than 50, promoting the green and low-carbon nature of the automotive supply chain and enterprises.

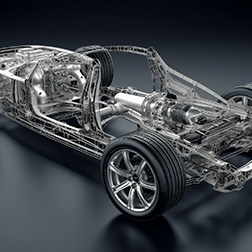

At present, 85% of parts can be designed with standard packaging based on size standards to meet transportation needs, while the remaining 15% of parts require non-standard packaging and the packaging size can be customized according to specific requirements. Whether it is standard or non-standard, with cushioning lining, it can meet industry needs. ALSCO provides comprehensive parts packaging solutions for automotive power systems, electrical systems, chassis systems and body systems.

-

Power systemCondenser, heater, heater, engine assembly, etc.;Learn more

Power systemCondenser, heater, heater, engine assembly, etc.;Learn more -

Electrical systemLights, instruments, generators, controllers, steering gear, etc.;Learn more

Electrical systemLights, instruments, generators, controllers, steering gear, etc.;Learn more -

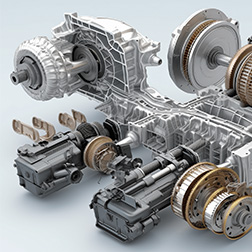

Chassis systemDrive shaft, vacuum booster, transmission, shock absorber, etc.;

Chassis systemDrive shaft, vacuum booster, transmission, shock absorber, etc.; -

Body systemSunroof, seats, rearview mirrors, bumpers, etc.

Body systemSunroof, seats, rearview mirrors, bumpers, etc.

| Model | Outer Size | Inner Size | Volume (m3) | Total box weight | Maximum load |

|---|---|---|---|---|---|

| M1(8FT) | 2550*2170*1400 | 2500*2130*1235 | 6.6 | 290 | 3000 |

| M1(8FT) | 2550*2170*1400 | 2500*2130*1235 | 6.6 | 290 | 3000 |

ALSCO will deliver the packaging to the parts supplier, and then the ALSCO logistics department will pick up the goods and send them to locations A and B. ALSCO is responsible for recycling the packaging, cleaning and maintenance, and finally returning it to the parts supplier.

Model change: from multiple packaging suppliers to ALSCO whole package, from one-to-many to one-to-one

Optimized packaging: Traditional packaging is optimized into lightweight, foldable, recyclable recycling packaging

Shared packaging: Utilize ALSCO’s existing FAW-Volkswagen standard packaging for convection and sharing

Cost reduction: 15% (the customer concluded this after conducting financial accounting on the packaging, logistics and other aspects of the supply chain)

Packaging standardization: For changes in packaging requirements, there is no need to use one-to-many;

Environmental protection: waste reduced by 52%